buy this on eBay for European

buy this on eBay for other countries/locations

China RC-113M Compact Panel Differential Thermostat - wholesale price, user manual, troubleshooting, wiring diagram, Setting guide video, and alternatives

113M PID thermostat makes the temperature changes gradually rather than sharply, which helps reduce the probability of dead eggs meanwhile, change the sex ratio by the finely controlled incubation temperature on reptile eggs.

Minimum Bulk order Amount: 200 USD

Features of the digital PID thermostat RC-113M differential controller are as follows:

- With adjustable limitations for aimed temperature and Calibration value;

- Within PID (Proportion Integral Derivative) algorithm.

- Auto memory exists data if the electricity is off; need not configure it again once the power is back.

- With 0.1°C precision and the accuracy as high as ± 0.1°C between 25°C to 42°C;

- Alarm once room temperature exceeds the measurable temperature limit.

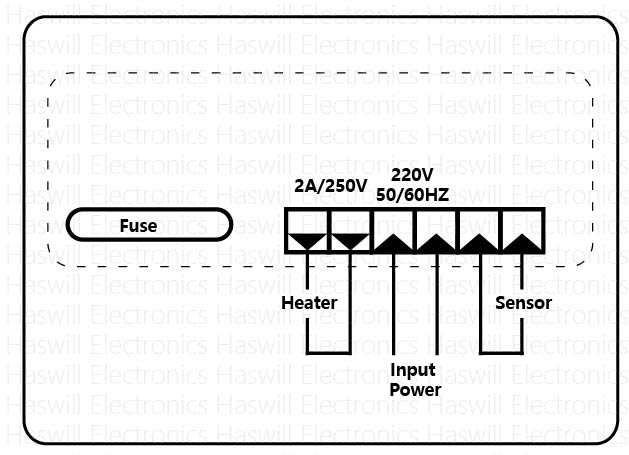

- Offers a replaceable fuse that protects this unit on the end of the chipset;

What is PID Temperature Controller?

In plain terms, PID is a kind of arithmetic. It considers the inertia and cumulative gap when calculating so that reaches accurate and optimal control. You may visit Wikipedia for a deeper study.

Why use PID Temperature Controller?

When applying the PID to the incubator controller, the benefits are as follows

Reduce the Death Rate of Egg

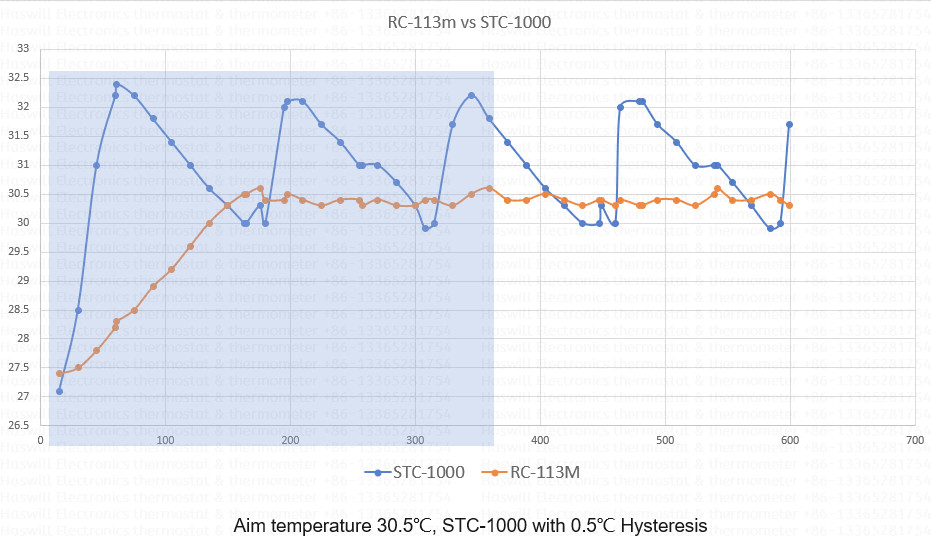

People use various heaters to help eggs hatch, and almost all heaters exist after heat (excess heat), making the temperature higher than expected. Even if you use a controller like STC-1000, you may not get a baked egg since STC1000 turns off the heater, but the residual heat could kill the embryonic tissue in the egg.

Temperature Controller with PID makes the Temperature Changes Gradually

The common controller can only turn on/off the heater; they are relay-embedded thermostats, and just like a switcher, it can not control the afterheat.

However, the PID thermostat could gradually rise since it adjusts the heater’s power rate by strictly manipulating the output electric current. Lower power means lower afterheat/Residual heat. This is how the PID controller reduces the death rate of eggs.

PID Controller Extend the Heater’s Lifetime

Some users like to set a small temperature hysteresis/return difference (for example, 0.5℃) and wish to maintain the incubator room temperature in a narrow range, it works but brings us a new problem, that is the service life of the heating unit will become shorter, because of the heater startup and shutdown frequently. Maybe the heating strip will not cost too much, but what about other types of heaters, and one more thing, the temperature controller with a good quality relay which max support turns on/off 100,000 times.

RC-113M PID Temp Controller without the relay, but within an SRC unit, the PID Thermostat is always working from the moment of itself powered on; it could realize a narrower temperature range meanwhile avoid turning on/off in a short time.

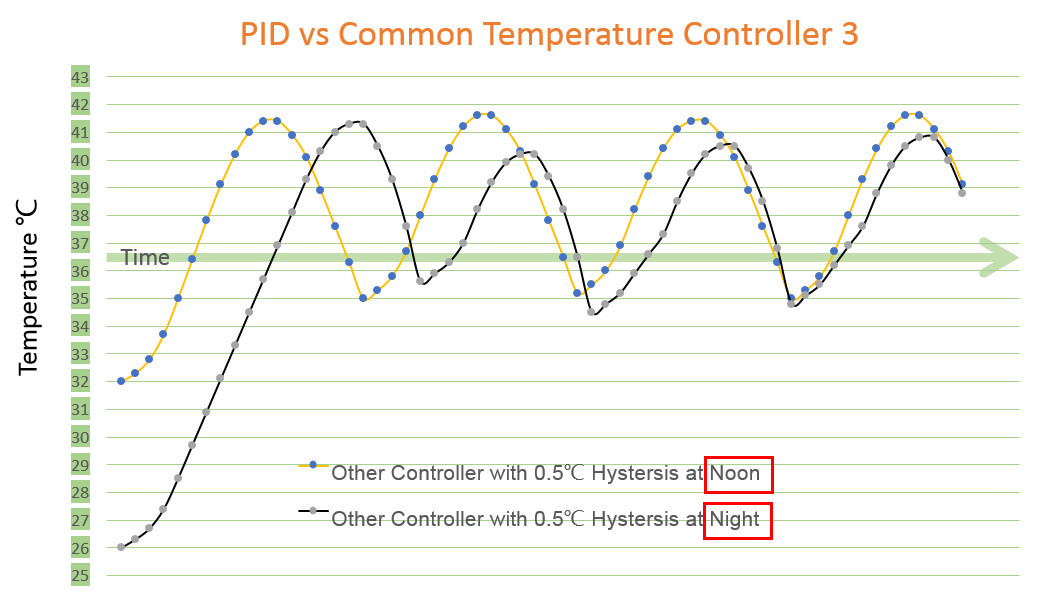

PID Controller reduces the “Day and Night Temperature Difference” Influence

The temperature difference between day and night in some places is usually beyond what we imaged, the night air cold, noon temperature hot, a common controller could maintenance a constant temperature range, but the temperature span is usually not small enough, what worse is the range will change with the temperature outside.

e.g., Let’s set the “target temperature” as 36.5℃ and set the “return difference” as 0.5℃ in the STC-1000, then the expected range should be from 36 -37 ℃, But you will find

-

-

- The actual temperature range at noon might be 35.0 to 41.6 ℃. Since room temperature is as high as 32°C, the thermal loss is slower, and the afterheat also disappears slower.

- The actual temperature range at night might be 34.5 to 41.3 ℃. Since the room temperature at night is only 26°C, the thermal loss is faster than in the day, same as afterheat.

-

In other words, the daily incubator temperature span is actually from 34.5 to 41.6 Celsius Degree, 41.6-34.5 = 7.1 ℃ or even wider. This is why many chicken farmers try but fail to find out why so many dead eggs.

The PID controller is more intelligent in response to external temperature change because the temperature change speed is one of the important factors to the PID Controller; briefly, it will output a stronger current at night and offers a weaker current at noon.

A Narrower Temperature Range Helpful to Incubating Gender Selection.

As we mentioned above, the PID unit provides fine-tuning temperature control. It allows incubates more female reptiles or for the opposite purpose.

Front Panel of RC-113M Thermostat

Tips:

- The red snow icon and fan icon are useless in 113M, and the digital tube screen is also used in other temperature controllers.

- The red small bell is for alarm once the sensor error or temperature exceeds the range -15 ~ 110 °C。

- The red “Set” font appears when the user configures this controller.

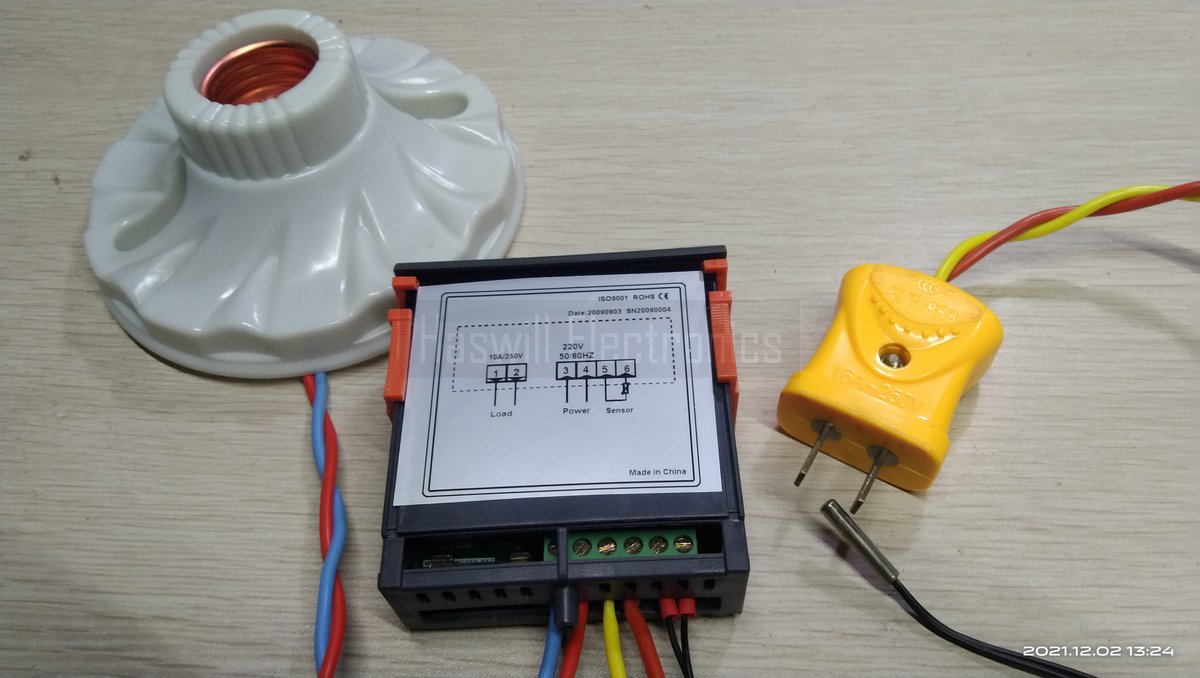

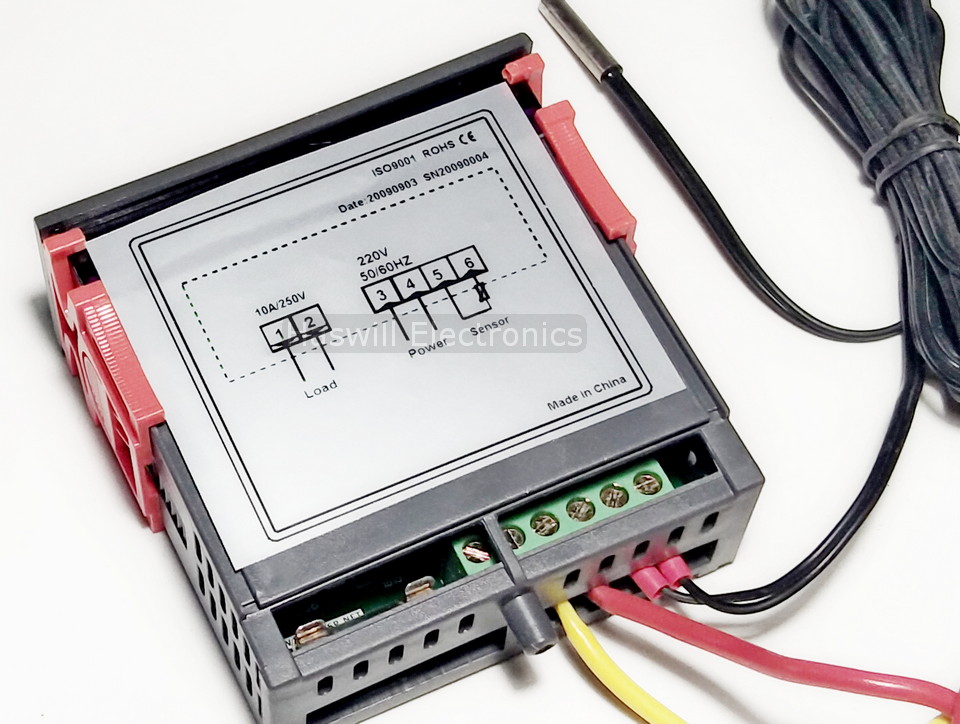

Back Panel & Wiring Diagram of 113M PID controller

Attention: The current passes through the inside of the equipment, which will make the SRC hot. Although there is a heat sink and fuse inside, the heat dissipation efficiency is limited, hence the load power must not exceed 500W. If the device does not work, try replacing the fuse.

Function Menu

| Code | Function | Min | Max | Default | Step |

|---|---|---|---|---|---|

| F01 | Lower Limit for SP | -10.0 | SP | -10.0 | 1.0 |

| F02 | Upper Limit for SP | SP | 100.0 | 100.0 | 1.0 |

| F03 | Calibration (°C) | -7 | 7 | 0 | 0.1 |

How to set the target temperature range? Let’s call the target temperature as SP (set-point)

- Press the “SET” key, and you will find the default value jumps,

- Press the “UP” and “DOWN” keys to change SP, which LS and HS limited;

- It will back to normal status in the 5s if without operation.

Tips:

- There is no temperature difference / Hysteresis in this unit, and you need not find it for tuning;

How to configure the other parameters?

- Hold the “SET” key for 3s to enter the function code interface, and you will see F01;

- Press the “SET” button to see the existing value;

- Press the “UP” or “DOWN” keys to change data;

- Press the “SET” to save the new value, and the screen shows F01 again;

- Now Press the “UP” or “DOWN” keys to switch to F02, F03;

More Tips:

- Repeat Steps 2 – 5 to adjust other parameters;

- Press the “RST” key to quit from setting mode and back to normal status;

- All new data will be auto-saved, and it will back to normal status in 15s if without operation.

- Change the F01 and F02 first if you can not set the SP to your aimed temperature.

- the max controllable temperature is 100℃, thus this unit should not be taken as the oven temperature controller.

RC-113M PID thermostat Troubleshoot

A buzzer inside of the 113M controller, thus you will find it scream once an error happens, and there are three types of code as follow

- EE.E could be triggered by three reasons

- Circuit of thermistor short or open

- thermistor Temperature >110°C

- thermistor Temperature < -15°C

- EE.H means the thermistor Temperature >110°C

- EE.L means the thermistor Temperature < -15°C

User Manual of RC-113M PID Controller

- English Version User Manual for PC: User Manual of RC-113M thermostat (English).pdf

- English Version Quick Guide for Mobile: Quick Start Guide of RC-113M thermostat.pdf

RC 113M user manual in Russian

регулятора температуры RC-113M - Краткое руководство пользователя.pdfPID RC113M Thermostat user manual in Spanish

Manual de usuario de Termostato PID RC-113M en español.pdfRelated Questions

How to change the humidity in the incubator?

It is easy to raise it, just put a plate into the incubation box and then fill some water, but if you want to reduce the moisture from the air, you can try putting in some burnt lime or other materials that absorb moisture easily.

FAQ of Haswill Compact Panel Thermostat

- How to avoid buying Inferior temperature controllers?

here is a simple method, that does not require professional knowledge. - How to get the price?

Click the inquiry button, and finish the form, You will get a reply in a few hours. - Celsius VS Fahrenheit; and Voltage

All of our digital temperature controllers default in Celsius degrees, and part of them is available in Fahrenheit with different minimum order quantities;

Besides the 220V AC (±15%), these electronic temperature controllers also are available in 110V AC, 12V DC, and 24V DC (110 / 24 /12 Volts ). - Parameter Comparison

Catalog of Compact panel digital temperature controllers - Package

The standard package could load 100 PCS / CTN digital temperature controllers. - Accessories

We suggest you buy 5% ~ 10% spare parts like clips and sensors as stock. - Warranty

Default one-year (extendable) quality warranty to all our controllers, We will offer a free-of-charge replacement if found a quality defect. - Customization Service

If you can not find a suitable temperature controller on this website, We will help you develop it based on our existing mature products ;

Thanks to China's complete set of related industry chains, our customized thermostats are of high quality and low price;

the MOQ is usually from 1000 pieces. don't hesitate to contact us for customization services.

or more questions? Click FAQs

Minimum Bulk order Amount: 200 USD

Voltage

Regarding the voltage of this electronic temperature controller

- 220V AC (±15%) as the default, Without MOQ (minimum order quantity) requirement, it is ok even you want to buy 1 piece;

- 110V AC (±15%) with MOQ 200 PCS;

- 24V DC with MOQ 50 PCS;

- 12V DC Without MOQ requirement, just 1 PCS is ok, it is ok even you want to buy 1 piece;