Last updated on March 19th, 2024 at 10:40 am

What kind of temperature controller can we customize?

The temperature controller is a digital product that owns conditional switchers that will auto-turn on/off the related relays to connected loads, they are also called thermostats; According to the load type and target temperature range, there are many temperature controllers for different application scenarios, e.g.

- The metallurgical industry usually requires temperatures as high as hundreds of degrees,

- agricultural greenhouses require room temperatures of more than twenty degrees,

- The storage and transportation of foods require temperatures below 10 degrees and lower, what Haswill Electronics is good at is just this field, our controllers mainly connect to the compressor, which offers cold air to adjust the room temperature;

Before using a thermostat, the user must set a target temperature range, according to which the temperature controller will decide the power state of the relay to the loads. regarding the target temperature range, there are 3 ways to set it, please reference it from here.

Why customize the temperature controller?

There are many classic temperature controllers on the market, e.g.

- STC-1000 thermostat owns dual relays, one for controlling the compressor, and another for controlling the heater;

- STC-8080H defrost temperature controller also offers two output relays: one for the compressor, and another for the defrosting unit;

- STC-9200 thermostat owns 3 relays: one for refrigeration, the 2nd for defrosting, and the last one for controlling the fan which is near the evaporator;

- TCC-2320A could control both the compressor and the light, once the user opens the door of the cooling beverage cabinet, the light will turn on.

However, it does not mean the existing temperature controllers could satisfy all your requirements, e.g.

- you may feel the functions of the STC-9200 defrosting thermostat are too much, you want to cut part of it; meanwhile, add or adjust part of the functions to the top level.

- You might want a new look or a revolutionary way of interacting to stand out from the competition and gain more market share.

- With the advancement of technology, many household appliances have added Internet control functions, and the development of commercial refrigerators is slower than that of household refrigerators.

- You wanna use the touch-sensitive keys instead of physical buttons.

How to custom a new temperature controller?

As you know the most essential parts of designing and developing a new temperature controller include:

- Mounting dimension: it is decided on the back panel size and chamber capacity, if your panel is too small, you should use a compact panel thermostat but not a bigger one, that is why we put it on position one.

- Front panel size: more and more factories adopt larger panels than before, big panels offer bigger and clearer fonts and more intelligent buttons, but please learn that the big panels mean big package volume and higher shipping cost;

- List the functions: tell us what functions your new controller will cover,

- Control the compressor,

- Control the defrosting by time or by temperature?

- Do you want a relay to control the evaporation fan?

- Do you want like a channel to turn off/on the Illuminating lamp?

- Do you need the demist relay for your glass freezer?

- Do you want the water dripping time? which was designed to prevent the water from freezing again.

- What is your plan once the sensor error?

- How is the alarm logic going?

- Do you need the temperature controller to connect to the internet? RS485, IoT, wifi, 4G?

You were encouraged to show us the function menu list, from where we will learn all the details of the parameters, e.g.

| Category | Code | Function | Min | Max | Default | Unit | |

|---|---|---|---|---|---|---|---|

| Defrosting | F1 | Defrosting Lasting Time | 1 | 120 | 10 | Min | |

| F2 | Defrosting Cycle / Interval Time | 0 | 120 | 6 | Hour | ||

| F3 | Defrosting Cycle / Interval Time Count Mode | 0 | 1 | 1 | °C | ||

| 0 | The sum working time of the controller | ||||||

| 1 | The sum working time of the compressor | ||||||

| F4 | Water dripping Time | 0 | 120 | 3 | Min | ||

| F5 | Defrosting by, | 0 | 1 | 0 | Min | ||

| 0: | Electric-Thermal | ||||||

| 1: | Hot Gas | ||||||

| F6 | Defrosting Stop Temperature | -40 | 50 | 10 | °C | ||

| Fan | F7 | Fan mode | -180 | 300 | d | S | |

| F8 | Delay Time for the fan 1st time running (count time from the moment of the F4 over) | 0 | 300 | 30 | S | ||

| Temp | F9 | Delay Time for the compressor Protection | 0 | 10 | 0 | °C | |

| Alarm | F10 | Alarm Delay time from the controller power on | 0.1 | 24.0 | 2.0 | Hour | |

| F11 | Alarm Over-Temperature Value | 0 | 50 | 5 | °C | ||

| F12 | Alarm Delay time after F10 (count time from the moment of the F10 over) | 0 | 120 | 10 | Min | ||

| Temp | F13 | Temperature Calibration | -10 | 10 | 0 | °C | |

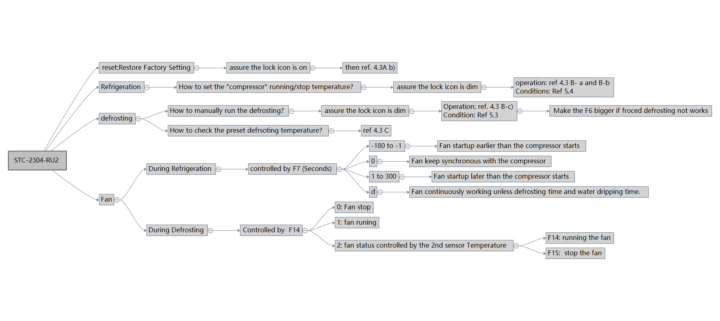

A mind map will help us figure out your logic easily

we will design a brand new circuit board or modify an existing board according to the above functions.

- Select a sensor and cable, covered by the TPE or rubber, with metallic ends or plastic housing, or a magnetic end, 2 meters cable or longer?

- Icons & typeface style: we have a collection of classic icons and light styles for selection, and welcome to offer new designs if you want to.

- Wiring Diagram: you may offer it to us, and Haswill Electronics could draw it too.

- User manual: you can design and create a user manual, share the PDF with us, and we will print it for you, it is free of charge from 3000 PCS.

- Video tutorial: we can create a user guide video according to your requirements and help your end users learn how to set up and use the product in a matter of minutes; what you need to do is just offer the caption/subtitle/voice in your language if it is not in English.

- Packing box: we will share the dimensions and drawings of the packing box with you so that you can design the pattern, it is free of charge to print from 500 PCS.

Once we get all the data and your requirements, we will analyze these documents, and then give options or suggestions.

How much it will cost to customize a digital temperature controller?

The development cost is mainly up of three parts:

- Mold fees:

- If you dislike all existing molds and want to develop a new one totally, the mold fee could be 5000 USD to 10K USD according to the size, the fineness of the mold, and the human-machine interaction mode.

- if you will adopt an existing mold and if it works well, then congratulations! no fee!

- if you agree to utilize an existing mold, but part of it is workable, for example, the back panel and room chamber are enough, we just need to make a new mold for the front panel, and you only need to pay for that part.

- Development fee:

- If your new design is based on an existing controller and is easy to modify based on it, the cost could be only 300USD or less;

- But if your design has a big difference from current products, it could be 1000USD or higher.

- If you can offer the firmware, we will do the rest jobs, like designing and producing the circuit board and outer shell, please understand we will charge a development fee from 1000 USD to 5000 USD, the specific amount depends on how complex your project is.

- Product Unit Price

- first of all, any customization order for digital temperature controllers should be no less than 500 PCS or 1000 PCS depending on the complexity of the product ;

- the more products you buy, the lower price you will get.

- As you know the unit price from European / USA manufacturers is usually 60 USD or 80 USD each, but from Haswill Electronics, the same quality products are usually no higher than 20 USD /PCS; please find other suppliers if your target unit price is extremely low (for example 3.5 USD) which means use recycled and low-quality raw materials, sorry Haswill Electronics does not produce that poor quality products.

How long it will take to develop a new temperature controller?

- It will take 4-6 weeks to offer the first samples if it is not peak season;

- If the products are based on the existing controller, 2-4 weeks is enough to design and make samples.

- Once you get the samples, test them, and give feedback to us as soon as possible, we will re-check and modify the plan if necessary, and then deliver new samples to you.

- Once you confirm everything is ok, we are going to bulk production.

We hope this article can help you figure out most questions about how to customize a temperature controller from China Haswill Electronics, just contact us for deeper discussion.

Conclusion

ODM a digital temperature controller from China Haswill Electronics will take a few months and thousands of US Dollars depending on the specific product details.

Please share your plan with us to get an accurate quote.